Summary

- Closed for EoI

- Profile Type

- Business request

- POD Reference

- BRBE20250225014

- Term of Validity

- 25 February 2025 - 25 February 2026

- Company's Country

- Belgium

- Type of partnership

- Outsourcing agreement

- Targeted Countries

- Serbia

- North Macedonia

- Romania

- Hungary

- Poland

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- The Belgian company is a world-leading producer of textile machines that has expanded into agro-bulk handling through a subsidiary. They produce the textile machines themselves but want to outsource some of the metalworking for structures that surround the machines themselves. The agro-bulk subsidiary is presenting unloaders to the market. Part of the construction of the metal structure is also te be outsourced. They are looking for a company who can act as supplier, with support of the company

- Full Description

-

The Belgian company is a world-leading producer of textile machines that has expanded into agro-bulk handling through a subsidiary.

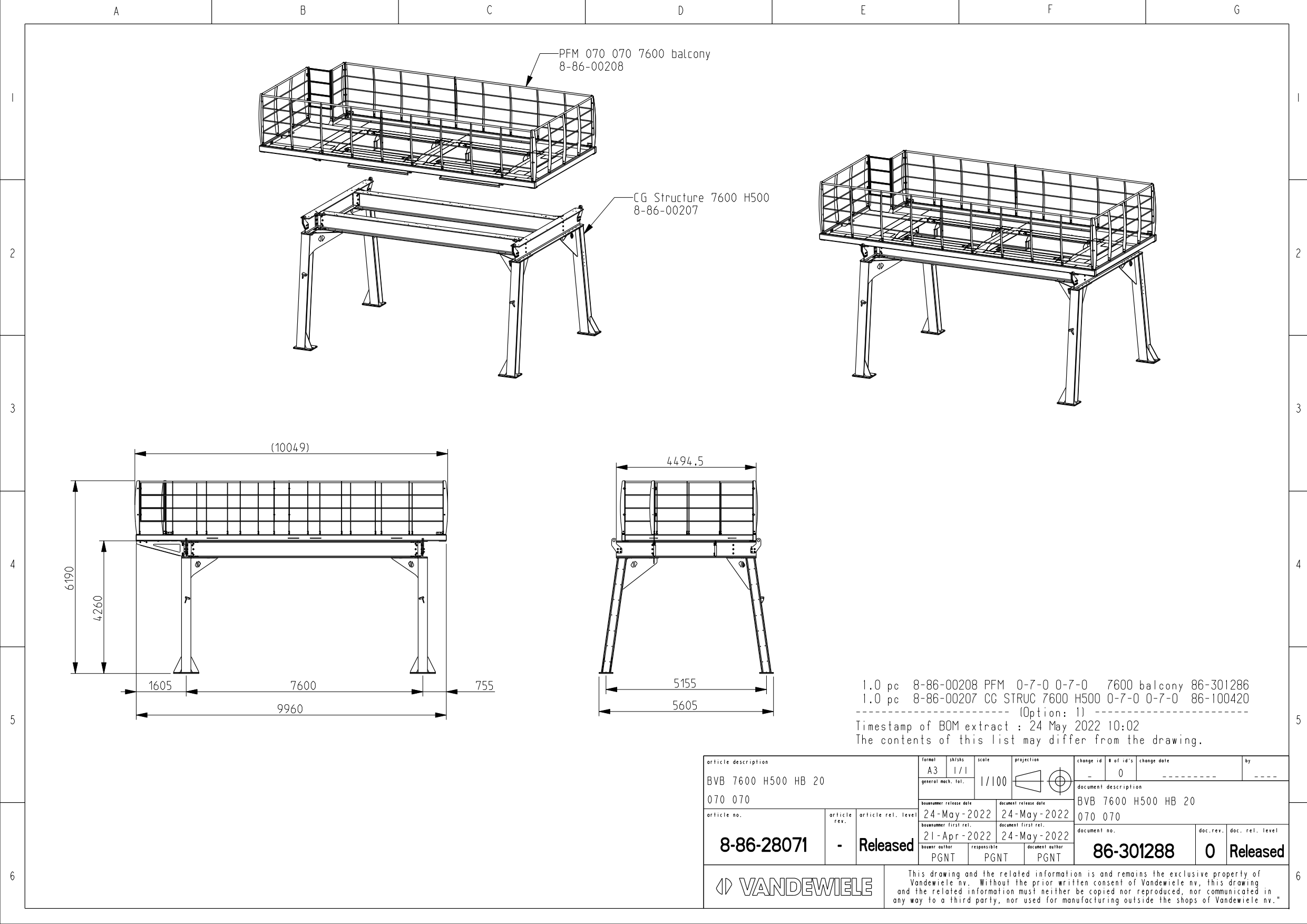

1. They produce the textile machines themselves but want to outsource some of the metalworking for structures that surround the machines themselves. These structures are designed by the company and fit the weaving machines and are sold together. Forecast is about a hundred constructions per year. The plans and prescriptions concerning the construction and the steel quality are part of specifications that will be provided by the company. In the beginning , support of the supplier is guaranteed. Checks will be done on all deliveries at the start. Technical drawings are included as attachment.

2. The agro-bulk subsidiary is presenting unloaders to the market. Part of the construction of the metal structure is also te be outsourced. The project is to subcontract the steel manufacturing of :

- Annual volume under normal economical circumstances: 20pcs/year (A photo of an unloader is attached).

- The gantry (from tires up to slewing ring)

- The main cabin

- The filter

o Sheetmetals are provided in dxf or stp. We don’t do detail drawing if sheetmetal has only to be cut. In case of bending, drawing is provided

Sheetmetal parameter (thickness and material) are provided in BOM table on head drawings or in bending drawing.

o Step file, presenting full detail 3D drawing

o Unless otherwise stated, all parts listed in drawings should be supplied.

Steel type :

o ST37 = S235

o ST52 = S355

o Triten : Triten

o Hardox 400 or 450 : Hardox from SSAB

Welding / Bolting

We don’t do welding drawings.

All structural welding to be performed full thickness and watertight. Accessories can be stich welded, like assembly 52288N in assembly 52280N

If no bolting is present in drawing, it means welding is supposed to be performed.

Bolts are included in scope of supply.

Coating

The standard coating system is:

- Boom, access stairs, gangways and guard rails: hot dip galvanized, following ISO1461

- Gantry, machine room, filter and other structures:

Sand blasted : SA 2.5 following ISO8501-1

Primer: BESA F-308/2 (anticorrosion enamel polyester/ polyurethane) and hardener = 70 μm (color: RAL 70267)

Finishing: BESA Alfapur 3795 (anticorrosion enamel polyester/ polyurethane) and hardener = 100 μm (color: RAL1007)

Nominal final thickness: 170μm with body-shop finish

Class C4 high according to ISO 12944-6

The supplier should be able to:

1) Welding: semi-automatic – arc welding

2) To saw, drill, paint HEA/B profiles

3) Lasercutting preferable 6m x 2m

Plate thickness 4mm to 25mm (some parts 30mm up to 45mm)

Steel grade S355 ans S235 and Hardox

4) Parts need to be wet painted

5) Assembled parts go up to 20T, so lifting Gantry of 2x12,5T for instance is possible

Most parts can be handled by lifting gantry up to 10T

6) Sandblasting activity is a benefit

7) Bending machine of 320T and 3m is a minimum, but if they can combine 2 x 3 to 6m bending machines it is a benefit

In the beginning , support of the supplier is guaranteed. Checks will be done on all deliveries at the start

The client is looking for a company who can act as supplier, with support of the client for both projects but is also open to work with two suppliers if this is preferable. Subcontracting, when applicable is done by the supplier who will stay the contracting partner. - Technical Specification or Expertise Sought

- Proven track record for creating metal constructions of a certain size. Tech specs for the unloader parts are to be found in the full description.

- Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

Partner Sought

- Expected Role of a Partner

- The partner needs to be able to produce the products in the requested numbers and with the necessary quality. The partners needs to be able to guarantee delivery deadlines as specified in the contract. They need to be able to work with the plans and drawings provided by the client and be open to collaboration and consulting by the client at the beginning of the collaboration.

- Type and Size of Partner

- SME 50 - 249

- SME 11-49

- Big company

- Type of partnership

- Outsourcing agreement

Dissemination

- Market keywords

- 08003005 - Other industrial machinery for textile, paper & other industries

- 08003007 - Other industrial equipment and machinery

- 08003002 - Hoists, cranes and conveyors

- Sector Groups Involved

- Textiles

- Targeted countries

- Serbia

- North Macedonia

- Romania

- Hungary

- Poland