Summary

- Profile Type

- Business Offer

- POD Reference

- BOLT20250417014

- Term of Validity

- 18 April 2025 - 18 April 2026

- Company's Country

- Lithuania

- Type of partnership

- Commercial agreement

- Supplier agreement

- Targeted Countries

- Latvia

- Slovakia

- Estonia

- Sweden

- Denmark

- Romania

- Spain

- Poland

- Austria

- Netherlands

- Czechia

- Germany

- Hungary

- France

- Finland

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- The Lithuanian company is creating user-friendly robotic solutions for the manufacturing sector. Besides this, it is offering no-code industrial robot programming technologies. The company is looking for a partnership under a commercial or supply agreement.

- Full Description

-

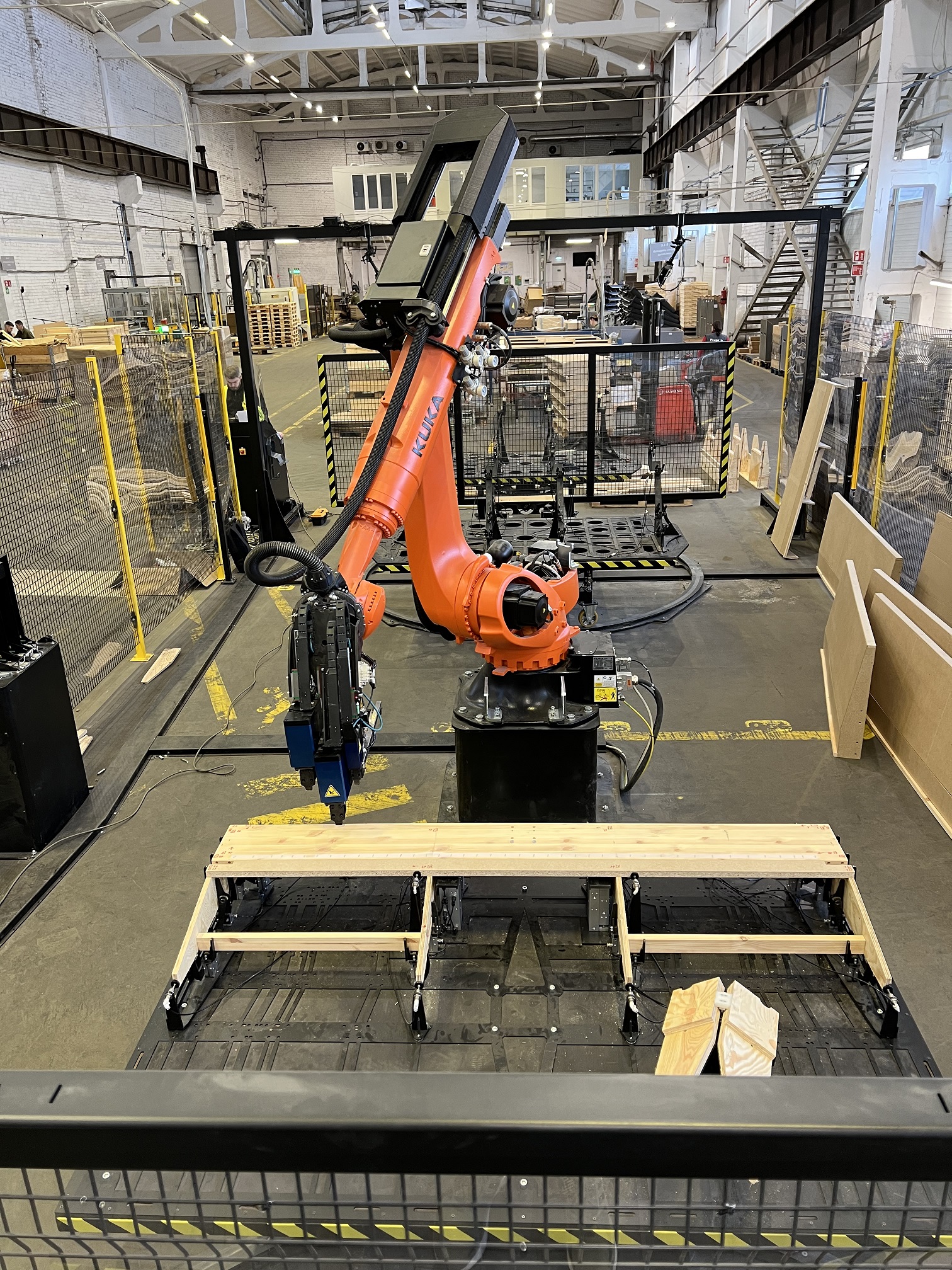

The Lithuanian company has specialized in user-friendly robotic solutions for the manufacturing sector and no-code industrial robot programming technologies since 2017.

The company's innovative technologies enable manufacturers to automate their processes without the need for complex programming. With their flexible and user-friendly solutions, businesses of all sizes can automate tedious manual labor, maintain constant quality, and improve overall efficiency, transforming the way they operate in the rapidly evolving industrial environment.

Main products & solutions are:

1. Easy to teach – no-code robot programming solution

Easy to teach (ETT) is a no-code robot training system that simplifies robot programming by allowing users to teach robots by demonstrating the task. This eliminates the need for coding expertise, making industrial robots accessible to small and medium-sized enterprises (SMEs).

2. Turn-key robotic solutions for manufacturing

The company develops ready-to-use robotic cells designed for specific industrial processes, eliminating the need for expensive custom automation solutions. These user-friendly robotic systems can automate manual production operations like painting, spraying, sanding, grinding, frame assembly, components manufacturing, cardboard package production and etc.

The company seeks to expand to new markets and establish new partnerships in the industrial manufacturing sector. Above mentioned types of solutions can be part of the partners' portfolio or can be acquired by end-customers who are manufacturing companies.

The company’s no-code robot programming solution can open doors to companies that previously might not have been considered for robotization as their production might have been too complex programming-wise. The "easy to teach" system could be used in robotic projects or distributed to other companies. Also, the standardized turn-key solutions could be a good product in your existing portfolio.

Commercial or supply agreement are offered to potential partners. - Advantages and Innovations

-

- Deep manufacturing insight: backed by over 20 years of hands-on manufacturing experience, including direct operation of a furniture factory.

- Industry-tested: Real-world deployments with international clients for various applications.

- Expertise in robotic integration and software development: The company combines in-house software innovation with practical integrator experience to deliver tailored, cost-effective automation solutions.

-No-code robotic programming: allows operators to program robots without any specific programming or robotics knowledge.

- Accessible automation for all: enables small and medium manufacturers to adopt robotics, not just large-scale factories.

-Flexible for high-mix, low-volume: designed specifically for environments where frequent product changes and manual tasks are common.

-Human expertise in a robot: workers can transfer years of skill and technique to a robot in minutes, enhancing productivity without losing know-how. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Not relevant

Partner Sought

- Expected Role of a Partner

-

The company offers robotic solutions and co-code industrial robot programming technologies. It seeks to expand to new markets and establish new partnerships in the industrial manufacturing sector.

Ideal partners can include:

• Robotic system integrators;

• Tool and solution providers;

• Consultants in the automation and manufacturing industry;

• Manufacturing companies (furniture, metal processing, automotive, aerospace, defence, etc.).

Commercial or supply agreements might be appropriate cooperation forms. Technical expertise in fields of automation and robotics, production operations is a benefit but not necessary. - Type and Size of Partner

- Big company

- SME <=10

- SME 50 - 249

- SME 11-49

- Type of partnership

- Commercial agreement

- Supplier agreement

Dissemination

- Market keywords

- 08002004 - Robotics

- Sector Groups Involved

- Mobility - Transport - Automotive

- Electronics

- Targeted countries

- Latvia

- Slovakia

- Estonia

- Sweden

- Denmark

- Romania

- Spain

- Poland

- Austria

- Netherlands

- Czechia

- Germany

- Hungary

- France

- Finland