Summary

- Profile Type

- Technology offer

- POD Reference

- TODE20250401011

- Term of Validity

- 2 April 2025 - 2 April 2026

- Company's Country

- Germany

- Type of partnership

- Research and development cooperation agreement

- Targeted Countries

- Sweden

- Spain

- Finland

- Netherlands

- Italy

- Portugal

- Norway

- Denmark

- France

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A German research center is developing advanced tungsten-based materials with unique properties. Industrial partners are sought to apply these technologies in sectors with extreme conditions, such as concentrated-solar power, heat exchangers, high-temperature power plants, turbines or aerospace. Manufacturers with expertise in AI-driven modeling and material design are welcome to co-develop novel applications and scale-up production. The aim is to apply for funding in future R&D calls.

- Full Description

-

Extreme temperatures, high mechanical stress, and harsh environments push conventional materials to their limits.

A German research center is currently spearheading an ambitious project focused on the industrial scale-up of tungsten-based special SMART materials and tungsten fiber-reinforced composites (Wf/W).

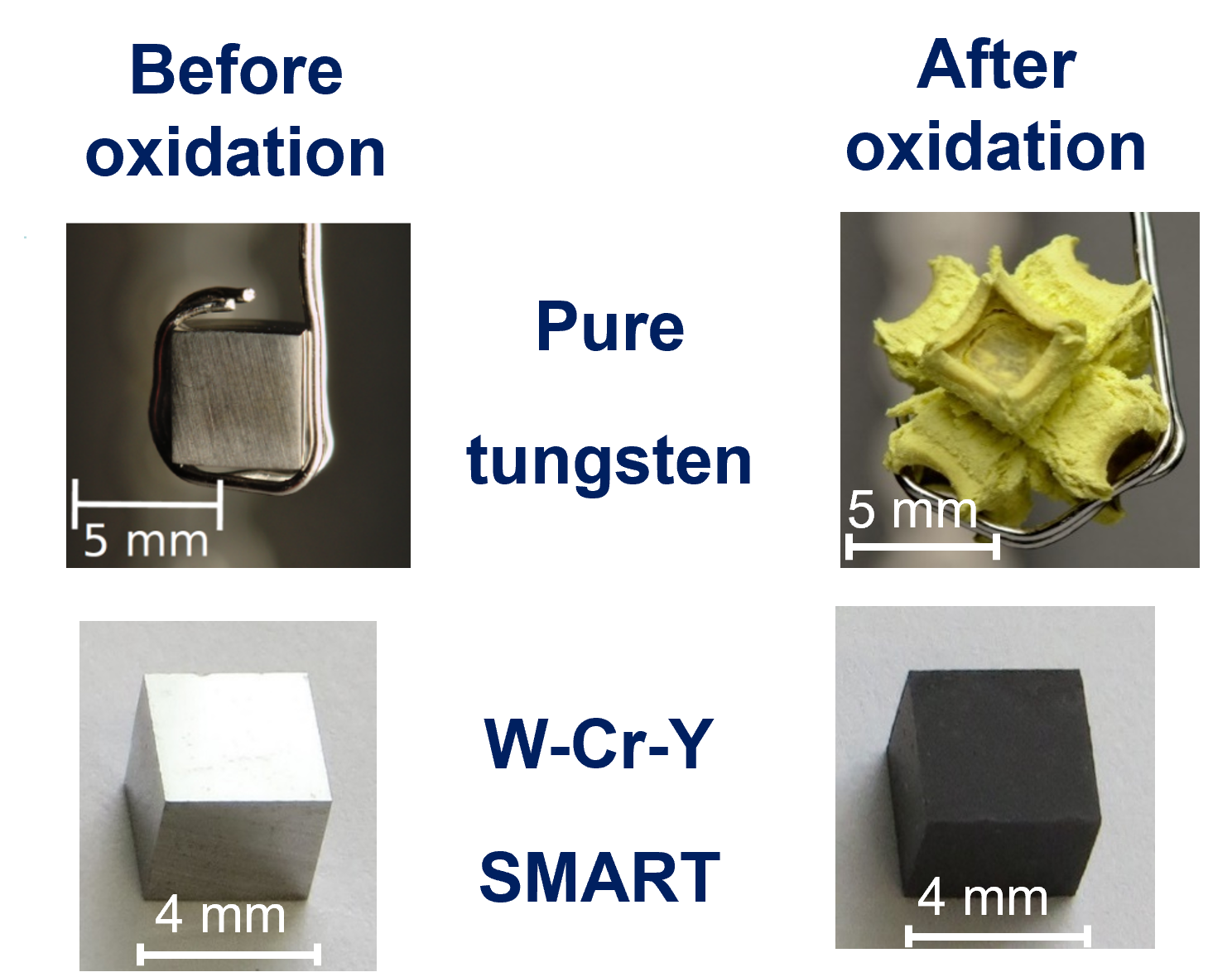

The SMART materials are Self-passivating Metal Alloys with Reduced Thermo-oxidation.

Originally developed for fusion power plants, these advanced materials offer unparalleled performance under extreme high-temperature and aggressive environmental conditions (oxidation, corrosion).

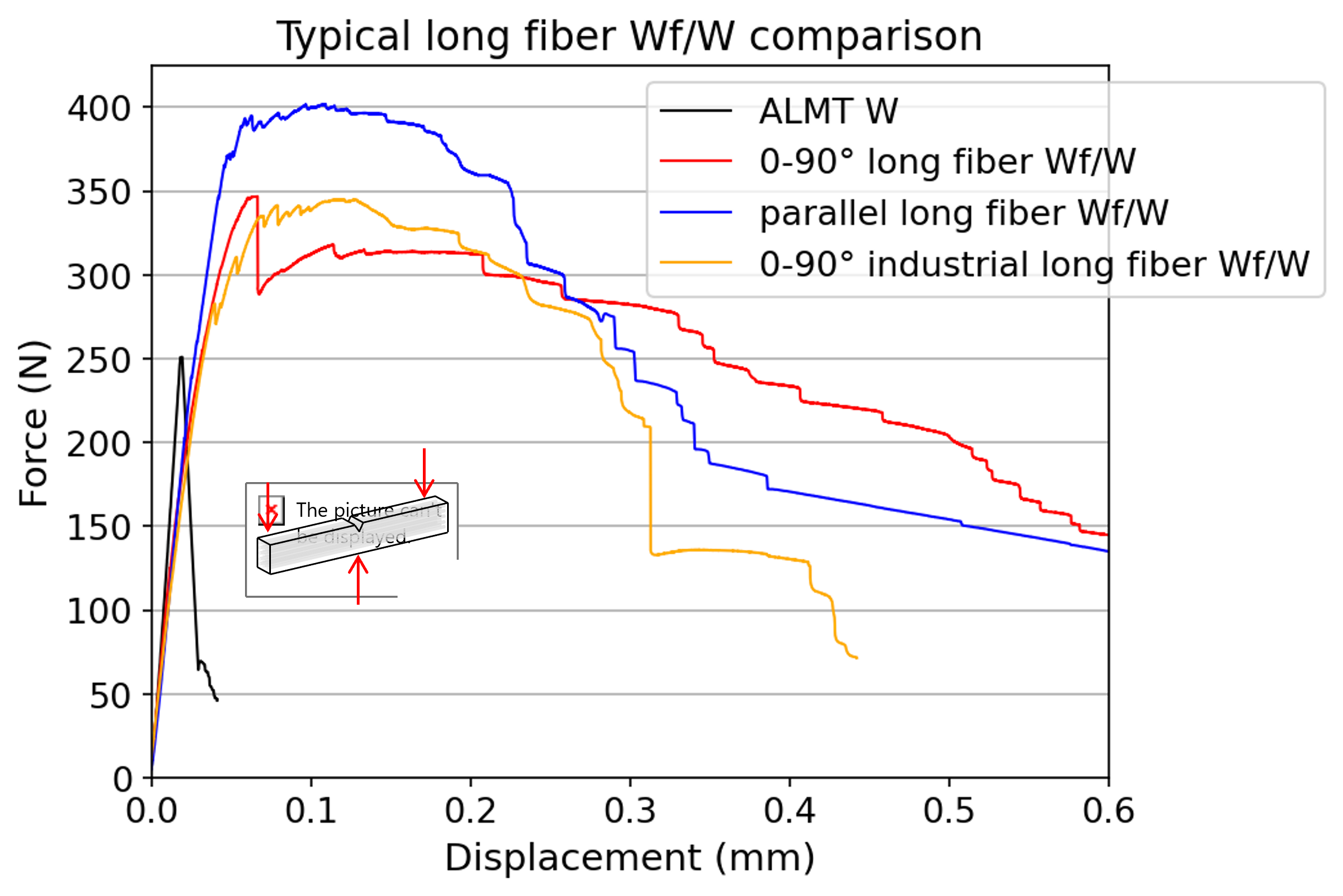

The materials form a protective chromium oxide layer upon air exposure, preventing the release of tungsten oxide. Tungsten fiber-reinforced composites (Wf/W) improve tungsten’s brittleness by enabling a pseudo-ductile fracture behaviour, increasing durability and damage resistance.

These cutting-edge material technologies have the potential to be transferred into applications across multiple high-tech industries. The research center is seeking industrial partners, advanced material manufacturers and material designers across the EU who would like to seize these opportunities and reach the next level.

The institute proposes to cooperate in a European project to further develop and adapt the materials to the industrial partners specifications.

Strategic Focus Areas and Applications

1. Designing components for extreme environments harnessing the exceptional thermal resilience, oxidation resistance and advanced functional properties of our materials, our project aims at delivering transformative solutions for:

• Concentrated Solar Power (CSP): Crafting state-of-the-art components for solar receivers that optimize energy capture and efficiency.

• Heat Exchangers and high-temperature power stations applications: Engineering sophisticated heat-transfer systems, including high-temperature piping, to elevate performance in thermal infrastructures.

• Turbine Technologies: Innovating next-generation turbine blades and leading-edge materials tailored for aerospace and energy sectors.

• High-Temperature Inert Technologies: Developing robust high-voltage contacts capable of operating at temperatures exceeding 1000°C, ideal for automotive and related applications.

• Aerospace: Advancing ultra-thin smart armour coatings to protect critical components in space and other demanding environments.

2. Pioneering advanced material synthesis technologies

The envisaged European project will propel material manufacturing into a new era by embracing cutting-edge synthesis and production techniques:

• Deposition Technologies such as chemical-vapor deposition and physical-vapor deposition (CVD & PVD): Employing vapor deposition techniques to create high-performance functional coatings.

• Additive Manufacturing (AM): Leveraging innovative 3D printing methods such as, f.e. Laser Beam Melting (LBM) and Electron Beam Melting (EBM) to fabricate intricate, high-performance components with unparalleled precision.

• Computational Material Design: Utilizing sophisticated modeling tools like CALPHAD and ThermoCalc to predict and optimize material properties, ensuring peak performance under extreme conditions.

The German research center is seeking industrial partners, especially manufacturers with expertise in AI data-driven modelling and material design, advanced manufacturing technologies, and high-performance engineering to co-develop novel applications and commercial-scale production, first and foremost in the abovementioned application fields and focussing on the mentioned technologies. Partners are being sought to form a consortium that will apply for funding in future international calls for proposals. - Advantages and Innovations

-

• High-Temperature Resistance – Both smart materials and tungsten fiber-reinforced composites (Wf/W) can withstand the extreme heat loads up to 10 MW/m2, maintaining structural integrity and suppressed oxidation at temperatures of 1000°C.

• Enhanced Safety – smart materials form a protective chromium oxide layer, preventing the release of radioactive tungsten oxide in case of air exposure.

• Increased Durability – Both materials withstand neutron radiation, extending their lifespan in fusion reactors.

• Improved Damage Resistance – tungsten fiber-reinforced composites (Wf/W) reduce tungsten’s brittleness, preventing sudden fractures and improving structural integrity.

• Lower Maintenance Costs – Longer-lasting materials reduce the need for frequent repairs and replacements, making fusion power more cost-effective. - Technical Specification or Expertise Sought

-

Especially sought are manufacturers with expertise in AI data-driven modelling and material design, advanced manufacturing technologies, and high-performance engineering to co-develop novel applications and commercial-scale production. Sought are collaborations with high-technology enterprises at the forefront of material design and advanced production techniques. Ideal partners are those pioneering in:

• Complex 3D shape fabrication via AM: Pushing the boundaries of what is possible in additive manufacturing to create revolutionary component designs.

• Development of smart coatings (ranging from 3 to 1000 µm): Innovating thin-film solutions that redefine performance in extreme environments.

• Component Manufacturing through AM: Realizing intricate designs and superior performance through state-of-the-art additive manufacturing processes.

The aim is to find partners in order to form consortia to apply for EU/international funding. - Stage of Development

- Under development

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 7: Affordable and Clean Energy

- IPR status

- Secret know-how

Partner Sought

- Expected Role of a Partner

- Expected role of the partner is to collaborate in the development of novel applications and commercial-scale production in the framework of future R&D projects.

- Type and Size of Partner

- SME 50 - 249

- SME <=10

- Big company

- SME 11-49

- Type of partnership

- Research and development cooperation agreement

Dissemination

- Technology keywords

- 04002009 - Turbines

- 02002002 - Coatings

- 02011001 - Aeronautical technology / Avionics

- 04002006 - Heat exchangers

- 01003003 - Artificial Intelligence (AI)

- Market keywords

- 06003001 - Solar/thermal energy

- 06002003 - Power grid and distribution

- 06007001 - Other energy production

- 06002001 - Oil, gas and coal

- 08001009 - Speciality/performance materials: producers and fabricators

- Sector Groups Involved

- Mobility - Transport - Automotive

- Renewable Energy

- Digital

- Energy-Intensive Industries - BioChemTech

- Energy-Intensive Industries

- Aerospace and Defence

- Energy-Intensive Industries - Materials

- Targeted countries

- Sweden

- Spain

- Finland

- Netherlands

- Italy

- Portugal

- Norway

- Denmark

- France